Have any questions?

+44 1234 567 890

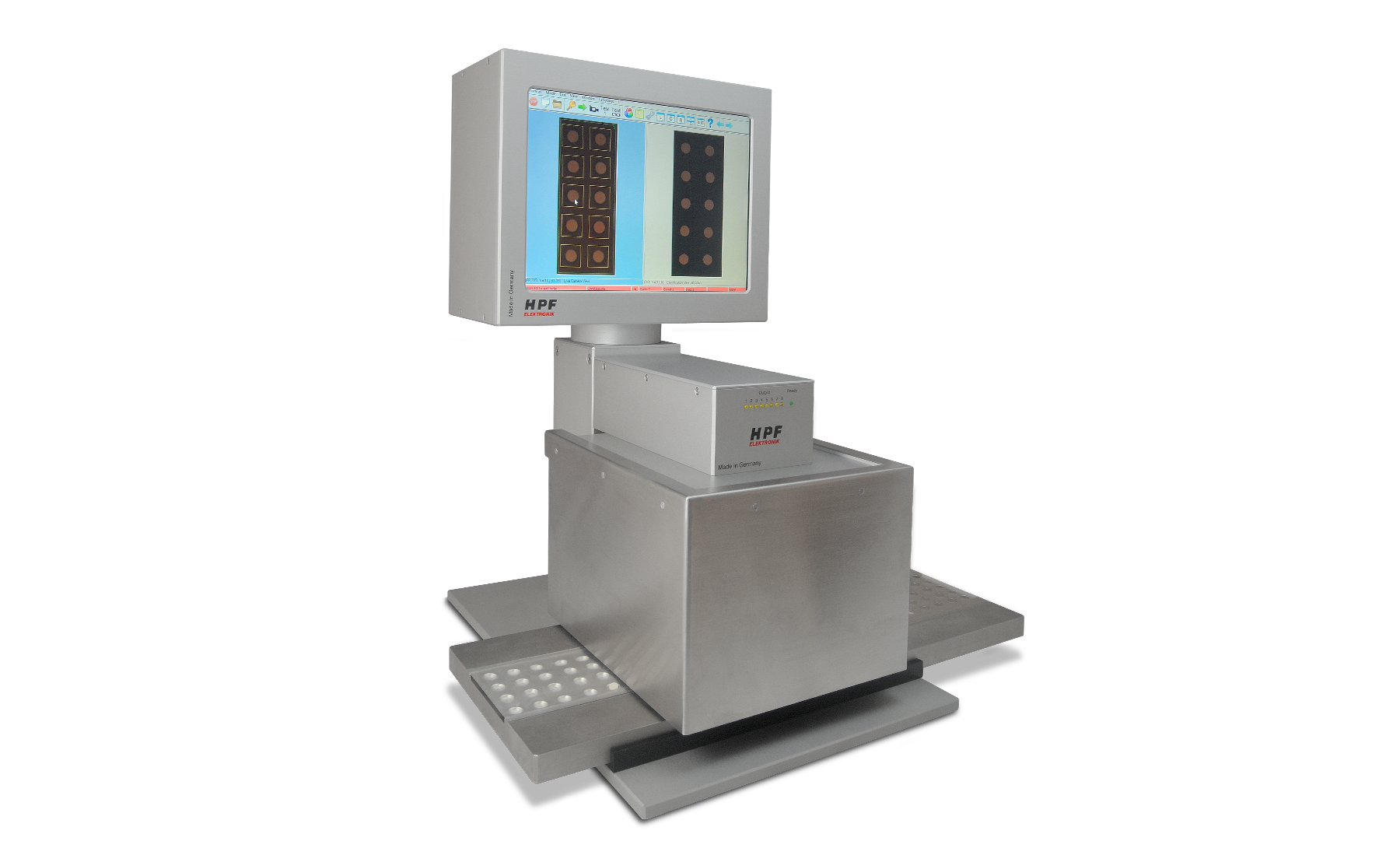

Camera Inspection System for recognition of colored objects packed in PVC foil or aluminum foil

Blister Inspection System EOK FA

The EOK-FA consists of a color camera, an industry-standard PC with color high resolution display and lighting devices as well as powerful state-of-the-art software.

Using the reflected light method, the product to be inspected is illuminated by white light. A temperature-compensated LED unit illuminates the product area evenly without glare. The color camera captures the image which is then processed by the IPC. A signal from the machine triggers and synchronizes image acquisition. Depending on factors like foil width and the distance from camera to product, different lenses can be used. The captured image is displayed on a high resolution display.

The software assists the user with every step of setting up a format, from the ideal settings for illumination and camera to product specifi c evaluation parameters. Our software package is capable of very high processing speed and offers an easy, comfortable and intuitive Windows embedded user interface. Packaging layout and color information can be set up quickly using the system’s teach functionality. Format parameters like product size tolerance can be easily adjusted via touch screen or a menu using a mouse, a keyboard is not necessary for operation.

Another feature of the EOK-FA is that that due to effi cient technical components and sophisticated temperature management in all areas – camera and lighting as well as the CPU/Display unit, there are no vent openings that might cause impurities that require cleaning or compromise functionality. Also, the system has no internal fans, so there are no moving parts inside. This, together with low internal temperature provides an extra long lifespan for the used components.

TECHNICAL DATA

Service Description

- Easy to manage the taught-in color classes and blister sizes

- Powerful analysis of the color classes

- Taught-in color classes are displayed

- Formats can be changed quickly and easily

- Integrated shift register

- Biometric user management

- Integrated password/user administration with 6 levels

- If packaging layout doesn‘t change, existing formats can be easily modified to be used with a new format

- Adjustable picture database for all types of images such as bad, teach, empty, and good images

- Significant evaluation statistics with detailed information on cavities and products

- Checking the color of tablets, dragees and capsules (including multi-colored and printed capsules)

- Easy operation with comprehensive and video-assisted help support

- Simple teach-in procedure with automatic search and find function for all products and colors within the blisters

- Tolerances for size and colors can be adjusted separately

Resolution camera

- Up to 12 MP, typically 2,4 MP (1936 x 1216 px)

Supply voltage

- 24VDC power supply is delivered according to configuration